The innovator in digital print finishing is now even further improved. Laser-sharp accuracy. The AeroCut X is the basic slitter/cutter/creaser.

The innovator in digital print finishing is now even further improved. Laser-sharp accuracy. The AeroCut X is the basic slitter/cutter/creaser.

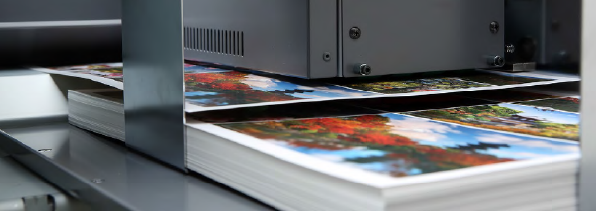

Extremely stable feeding.

Feeding is an important and essential part for any print finishing device. The AeroCut X has an innovative patented feeding mechanism, that drastically reduces risks of double feeds and misfeeds. It results in much greater actual productivity.

• Laser-sharp accuracy.

The AeroCut X is designed, built and calibrated with Japanese engineering and craftsmanship at its best. The robust full-metal machine body keeps top level of accuracy and finishing quality every time.

• True creaser adds value on digital prints.

AeroCut X is an ideal solution for finishing especially short-run digitally printed applications, such as business cards, post cards, invitations, greeting cards, leaflets, tickets and more. The AeroCut X saves times and costs for any print shops, inhouse printers, commercial printers etc.

Basic Functions:

• Creasing unit - The true rule & matrix creaser is equipped on the AeroCut X, allowing the machine to offer world-class quality creases on digitally printed stocks. Creasing pressure can be adjusted in 5 levels instantly by shifting the lever.

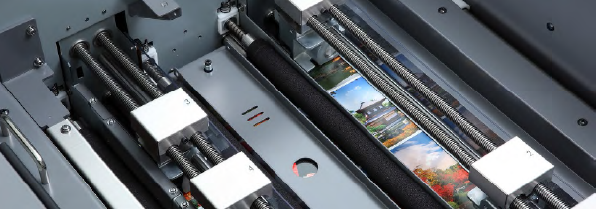

• Slitting / Cutting Units - The AeroCut X features 2 single blade slitters to trim top & bottom margins of sheets, and 2 double blade slitters, bleed centre gutters and deflect wastes into a waste bin. The durable guillotine cuts stocks up to 400gsm in weight. All the slitter and guillotine blades are self-sharpening.

• Feeding unit - The patented " Tri - s u c t i o n f e e d i n g mechanism" reduces risks of doublefeeds and mis-feeds drastically, therefore it prevents paper jam inside and enhances actual throughput. Feeding Unit The AeroCut X feeds printed stocks oneby-one from the top of the ream on the feed tray. The air-suction top feed system feeds even coated stock precisely without damage. There are several features to ensure feeding several weights and qualities of stocks every time..

• Doublefeed detector - New ultrasonic double-feed detection now allows more accurate double-feed control, even when feeding black or full-area printed sheets. When two sheets are detected, the machine briefly adjusts the blowing intensity and repeats the feed. This ensures top feeding reliability.

• Intuitive operation – Thanks to the 7" built-in touch screen, the AeroCut X allows operators to set job programmes and run the machine intuitively and instantly.

• Flex mode - Flex mode allows operators to cut multiple size of cards from a page and add desired numbers of creases on these. It enables designers and printers to create new aspects of applications.

• Robust slitters and guillotine - The self-sharpening slitters and a guillotine unit allows the machine to cut even 400gsm stocks crispy every time, for the long time.

• Instant job change - The AeroCut X can change jobs instantly, therefore is the ideal solution for finishing digitally printed applications, such as business cards, post cards, greeting cards, tent cards, tickets, leaflets etc.

• Maintenance is easy - The AeroCut X now has detachable rollers, not only making cleaning easy, but gives better access to components in case of a paper jam.

Optional Accessories:

• Bar code reader - Adds the machine capability to read barcode for job changing and preventing contamination.

• LAN connector - Add the machine capability to connect to ethernet.

• Lytrod Intellicut Global 1 year license - PC software that allows operators to impose artworks on a paper at the most efficient way, to add barcodes and cut marks on PDF files. Job program can be sent to the AeroCut through ethernet right away.

• Perforation unitl - Including 2 perfing wheels. Enables the machine to perforate sheets along feeding direction. Manuall position set up.

• Belt conveyor delivery - 750mm length conveyor tray. Finished products will be neatly delivered.

© 2025 PALA, s. r. o. | All rights reserved.

Programia - internet shops